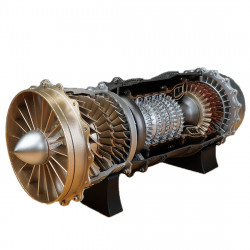

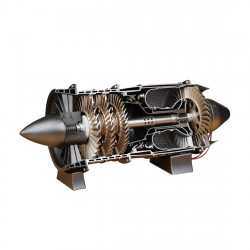

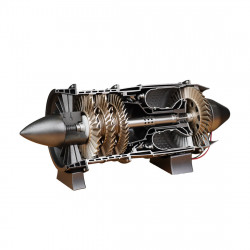

best metal engine model kits for adults

The Ultimate Guide to Metal Engine Model Kits

Metal engine models provide a perfect combination of detailed, true-to-life constructions, as well as the versatility of hands-on crafting that will inspire and create. This definitive guide examines the appeal, ingredients, construction, and pro tips for completing metal motor models, giving you the knowledge to create eye-catching models with confidence.

Metal Engine Model Kits - Why They Are So Appealing

Metal engine model kits are acclaimed for their realism, durability, and knowledge base. The engine models feature dynamic form and function and are designed for intuitive crafting and construction using only the highest quality stainless steel, aluminum, and brass. Their magic is in keeping the impact, the education, and the awe.

Unmatched Realism

They are precision-made metal parts that represent engine parts like a piston, crank, and cam. Most feature moving parts driven by an electric motor or hand crank, emulating actual engine function. Their shiny, anodized finishes add to their realistic looks.

- Detailed Interior: Recreated engine blocks, valves, and belts.

- Functional Mechanics: Moving components represent engine action.

- Beauty and Design: Show weightless metal finishes enhance the viewing experience.

Educational Value

Constructing a metal engine model can be a mechanical education, from the system of combustion cycle to gear interaction. Build your complex automotive systems and learn by doing as you build models ideal for both students, hobbyists, and professional mechanics.

- Learn by Doing: Discover how four-stroke and diesel engines work.

- Improve Hands-On Ability: Develop hand-eye coordination skills and perception in young children.

- Hands-On Application: Use what you learned and work on engines/tasks.

For Your Collection & Display

Finished models make impressive decor for offices, workrooms, or homes. Their complex patterns and utilitarian components receive admiration from guests and fellow fans. Collectors prize them for their quality and historical importance.

- Showpiece Quality: Gorgeous on a desk, table, or shelf.

- Discussion/Project: Promotes engineering conversations.

- Durable: Made of sturdy metal, it will last for years of display.

Water Line Metal Engine Model Kit, Exploded View

Knowing what you’re working with helps a lot when building this kit. Every aspect is used in some way to help the model work, which makes it come alive. Understanding of these parts helps to auto repair lifecase the explanation of assembling and disassembling.

Metal Parts

Kit comes with laser-cut stainless steel or aluminum components, including engine blocks, pistons, and connecting rods. They are generally pre-anodized for color and corrosion resistance, with 200–1000+ parts for the complexity.

- Exact Fit: Precision cut with laser accuracy for a perfect fit.

- Product Quality: Made of stainless steel or aluminum for durability.

- Variety: With its structure or moving parts.

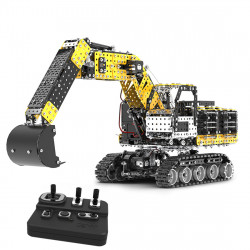

Power Mechanisms

Most are propelled using an electric motor or lithium battery (e.g., 3.7V 500mAh), turning moving parts to replicate the action of an engine. Others come with hand cranks for manual operation, and advanced versions feature sound or LED effects for realism.

- Standard of Electric Motors: Brine valve control, construct power 5V + or battery.

- Hand Crank: Provide manual operation of the motion.

- Bonus Features: Lights with LEDs, engine sounds with motor.

Assembly Tools

Kits usually come with (or need small tools like little screwdrivers, tweezers, and pliers. No glue is required, as pieces are screwed or “tabbed” together. Precision is facilitated with supplemental tools like magnifying glasses.

- Tools: Mini screwdrivers or spanners.

- Suggested Extras: Tweezers for small parts, pliers for bending.

- Fitting Style: Screw or hooks, fill. Type: Hook & bare.

Instruction Manual

An instruction manual with detailed, illustrated instructions is included. Manuals also contain an engine’s own history or engineering lessons that add to the learning process. For more complicated kits, clear directions are a must.

- Exploded Views: Good for understanding how the parts are assembled and don’t lose reference.

- Technical Notes: Describe engine mechanics or history.

- Clarity of Language: Make it relatable to all levels.

Choosing the Perfect Kit

Determining which kit is best for you comes down to your skill level, engine style, and time available. The intelligent decision creates a fun as well as fulfilling build. Keep in mind these things to fit your needs and desires.

Skill Level

For novices, beginner kits (100 to 300 pieces, 2 to 4 hours), with simpler designs like single-cylinder engines, are the way to go. Intermediate (300–500 pieces, 4–6 hours) and advanced (500+ pieces, 6–10+ hours) models can reproduce popular engines like the V8 or radial engine, providing a challenge for even experienced builders.

- Beginner: Entry-level units with four cylinders or singles.

- Lower: Inline-four or V-twin engines.

- Expert: These are V8, radial, or turbofan engines that are more complex mechanically.

Engine Type

Kits include all kinds of engines: four-cylinder, V8, radial, or even turbofan for aerophiles. Pick by interest—the car enthusiast may like the V8, the history buff the steam, or the hit-and-miss engine.

- Automotive: V8 or inline-four for gearheads.

- Aviation: Radial or turbofan for plane enthusiasts.

- Historical: For an old-timey feel, go steam or hit-and-miss.

Build Time and Space

Fast kits work for fast schedules, while involved models require devoted time and space. Be sure to have a large, well-lit table for both construction and storage. Look at the model size (e.g., 17x20x18 cm for a V8) so you can plan for the display.

- Fast Builds: 1–3 hours for easy-to-build kits.

- Long Projects: 6–10+ hours for complete models.

- Workspace Requirements: Space for parts, tools, and the manual.

Prepare for a Perfect Build

A good workspace and tools make it easy and prevent mistakes. Properly installed offers excellent accuracy and a very enjoyable shooting experience. Try these seven steps to make a strong beginning.

Workspace Essentials

Ensure you have a table that is clean and flat, and sufficient space for sorting parts and tools. Protect surfaces with a cutting mat and store mid-build on a puzzle mat. The bright LED lights will not strain your eyes under normal use for the product or when working on projects that require small detail.

- Tabletop: Hold parts, tools, and the manual.

- Surface Protection: Use a cutting mat or piece of fabric for safety.

- Good Lighting: Clear with the adjustable LED light source.

Tool Checklist

Assemble kit-provided tools (i.e., screwdrivers) and extras such as needle-nose pliers, tweezers, and a magnifying glass. Smooth cloth won’t leave prints on other surfaces. With everything you need right at your fingertips!

- Precision Tools: Tweezers and pliers are required.

- Magnifying: Lets you see clearly for small parts.

- Clean Touch: The Fabric keeps the metal smooth.

Safety Precautions

Wear protective glasses whenever working with metal parts in order to reduce your risk of eye injury from windshields. You may want to wear gloves for sharp edges, particularly if you’re working with a larger kit. Have a first-aid kit for small cuts or scrapes.

- Eye Protection: Shield from cut debris.

- Hand Protection: Gloves suitable for sharp or rough edges.

- Emergency Prep: Band-Aids for the little stuff.

Step-by-Step Building Process

Controlled attention will make for a happy build. Follow these steps, and you’ll have your metal engine model built with confidence and accuracy. And each phase is constructing another functional masterpiece.

Step 1: Study the Manual

Please read the manual carefully and refer to part numbers and follow the assembly sequences to prevent difficult scenarios and special instructions (i.e., special orders including special instruction/special bend specification). You would do better to learn the diagrams to avoid irreversible mistakes.

Step 2: Sort and Examine the Parts

Very carefully snip everything off the metal sheets, and keep organized by type (pistons, gears, etc.) in separate labeled containers. Inspect for any broken parts, and if found, contact the manufacturer if needed. The organization saves time.

Step 3: Put the Engine Block Together

Whether it be the engine block or frame, fasten the structural parts with screws or tabs. Keep all connecting links tightly connected and alignment level for stability, as the block anchors all the moving pieces.

Step 4: Install Moving Parts

Add pistons, crankshafts, and camshafts in the order outlined by the manual. Manually test the motion to see if everything is rotating smoothly. Use grease (included with the kit) when the instruction calls for it for gears or joints.

Step 5: Power and Accessories

Add the plug and accessories. Fit the electric motor, battery, or hand crank, wiring, or components in place as shown. Add in LEDs or sound modules for that extra layer of realism. Verify setup by testing the function.

Step 6: The Final Tests - Clean Up and Polish

Hand-run the model to determine if any jams, loose parts, or rough spots in motion exist. Tighten down any screws or components if it is the case. Buff them with a soft cloth for a showroom shine, and then either display them or store them safely.

Tackling Common Challenges

For the metal engine kits, however, it’s often the work can prove tricky, with misaligned parts and complicated instructions. These obstacles are overcome by proactive strategies. With these tips, your build will stay smooth and painless.

Part Misalignment

Tabs/screws may not be properly sized if not bent right or there is debris. Bend angles in tabs with pliers to exact requirements. Do make a connection after parts are cleaned, using a soft brush or compressed air to clean oneself.

- Bend to Match Slot Shapes: Yeah, twist. Bend and match to tabs for slots slotted.

- Clean Surface: Dust or metal shavings must be removed.

- Dry Fit: Test connections before cementing.

Fragile or Small Parts

Little bits, like valves or screws, may break or disappear. Manipulate with tweezers and as little pressure as possible. Set small parts into the tray and work over a protected surface to prevent loss.

- Handle Gently: Do not press down on vulnerable parts.

- Storage Provided: Trays stop lost parts.

- Replacement: Contact the manufacturer for replacements of missing or broken parts.

Complex Instructions

Cumbersome manuals can overwhelm builders. When you use the steps, do small stages, doing a section at a time. Pull up an online video or hobbyist forum (if you can’t understand the manual).