Assembly Clock

Want to get some ideas on Christmas gifts for adults? Here at Metal3dpuzzles, we are very honored to be able to help our users find the best gifts for all occasions, whether they need help finding the best Valentine's Day gifts, birthday gift ideas, or Christmas gifts. So whether you're looking for the latest and best gifts or need something thoughtful and unique for everyone on your Christmas shopping list without totally blowing your budget, we've got you.

1 Get A Warm Atmosphere!

A pleasant atmosphere is essential for Christmas. Additionally, Mr. Gort can make you feel cozy and at ease during the holidays. This mecha has an extra functional light feature. It's the perfect and original gift to surprise loved ones. This mech will function as a light after it is put together. It also has an astrological sign. It is incredible and lovely to display on a table, bookcase, shelf, or nightstand to enhance the beauty of your house.

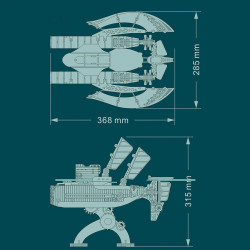

2 The Best Seller

Let us now present Fighting Shooter, one of our best-selling products. You may have even seen a YouTube unboxing video for it. It looks good and has a relaxed attitude.

He is renowned throughout the Moyu universe for being intelligent, dependable, dynamic, committed, and obstinate. It serves as the embodiment of all virtues. Who could not like a strong and kind hero like this? Whoever you give it to as a gift will be overjoyed when they open the package.

3 The Best Gift For The Coolest Person!

Everyone adores the mecha's sleek appearance. If you're wondering what could be more awesome than this, the answer is unquestionably yes—this is a mecha that doubles as a watch holder, and you can only find it at Moyu. It can serve as your favorite watch holder and a decorative.

4 Cool and Functional Mecha

His bravery and force are immediately apparent. In the boxing match, he emerged victorious with the gold belt. These mechas would rather fight one another close quarters to prevail than employ various powerful weaponry. This robot also includes a built-in Bluetooth speaker and a mobile phone holder to place on his head and shoulders. You'll quickly find that this is your favorite mech, I promise. Nobody could not like a product this good.

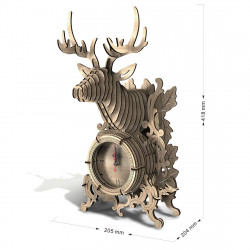

5 Tired of Ordinary Clocks, Try This Mecha Clock!

Such a machine would be too good to refuse; in addition to its elegant appearance, it functions as an LED digital clock. Different numbers are carved on the clear acrylic, and the bright RGB lamp distorts the digital effect to mimic the fluorescent tube glow clock's display. Diverse gradient colors are produced by each number, creating diverse aurora color effects and rainbow hues. This robot can serve as more than just a decoration; it can serve as a timely reminder to him. Getting such a gift on Christmas Eve will rank among his most excellent presents of the year.

6 Realize His Initial Dream!

Everybody dreams. Astronauts are undoubtedly what most people want to be, but some want to be scientists, and others want to be physicians and teachers. Astronauts are shining examples of human existence, delving into the secrets of the cosmos and the uncharted territory of humankind. One little child described his aspiration: "I want to be an astronaut when I grow up." After the dream fades, we become busy adults, yet life seems to settle into mediocrity. But it's not. We are still striving to fulfill our dream of becoming astronauts. Since birth, each person has discovered their existence, and life's journey is paved with obstacles and unknowns. To contend with challenges and unknowns head-on, we must never stop studying, increase the breadth of our knowledge base, and develop extraordinary bravery. Ride the wind and waves and triumph over thorns and thorns. Develop into a hero who rules your life and leads a bright one. Astronauts are accessible to anyone.

7 Choose Your Hero!

Nobody does not like heroes and aspires to be one. These robots are modeled after the most well-known warriors from ancient China! Its four generals are Lu Bu, Zhao Yun, Guan Yu, and Zhang Fei. People of all ages and generations have been inspired by their fabled actions. If he enjoys learning about the past, you've made the perfect present selection. This is a custom-made gift just for him. This isn't just any old mecha—it's a historical memorial that serves as a reminder to work hard, be passionate, and never stop refueling to succeed!

8 Start Hunting!

As long as his target cannot flee, Chaser Hunter, the hunter in the land of Moyu, is the most significant being and looks down on everything. His head doubles as a Bluetooth speaker so you can stream music from your smartphone. You can get a personal look at the excitement of hunting! Furthermore, you can put it together creatively and expand your mind. If it's feasible, you can not only put it together into the shape of a magnetic hunter, but you can also make other unusual shapes.

9 Girls' Favorite!

Congratulations! You've arrived at the ideal location if you're looking for ideas for gifts for women. This mech is simple to make and compact. Every component is lovely and accessible for ladies to put together. It also has a music box function; you can hear its beautiful sound after this mech is assembled! You have four alternatives to select from.

10 Try Your Luck

Is it hard for you to choose one mecha after watching so many? It's alright. We'll assist you in selecting. We now offer mecha surprise boxes. Your luck will determine this. We will randomly dispatch a Mecha to you once you place an order. The looks are based on our most recent models. Act quickly; you might receive a mecha worth more than the surprise box!

Who will you be spending your free time with that you love the most? You might worry that what you do during these hours will worsen your feelings. The next task, which should take three hours to complete, is to inspect these constructed models. These little fellas are full of energy; are you ready?